The objective & how I designed the dragster

In my engineering class with Mr. Buckley, we were asked to design the fastest car possible that meets the following requirements: we have to use the piece of wood that we are given, but it also has to have a certain weight (so that no one is getting an advantage by designing unrealistically small dragsters).

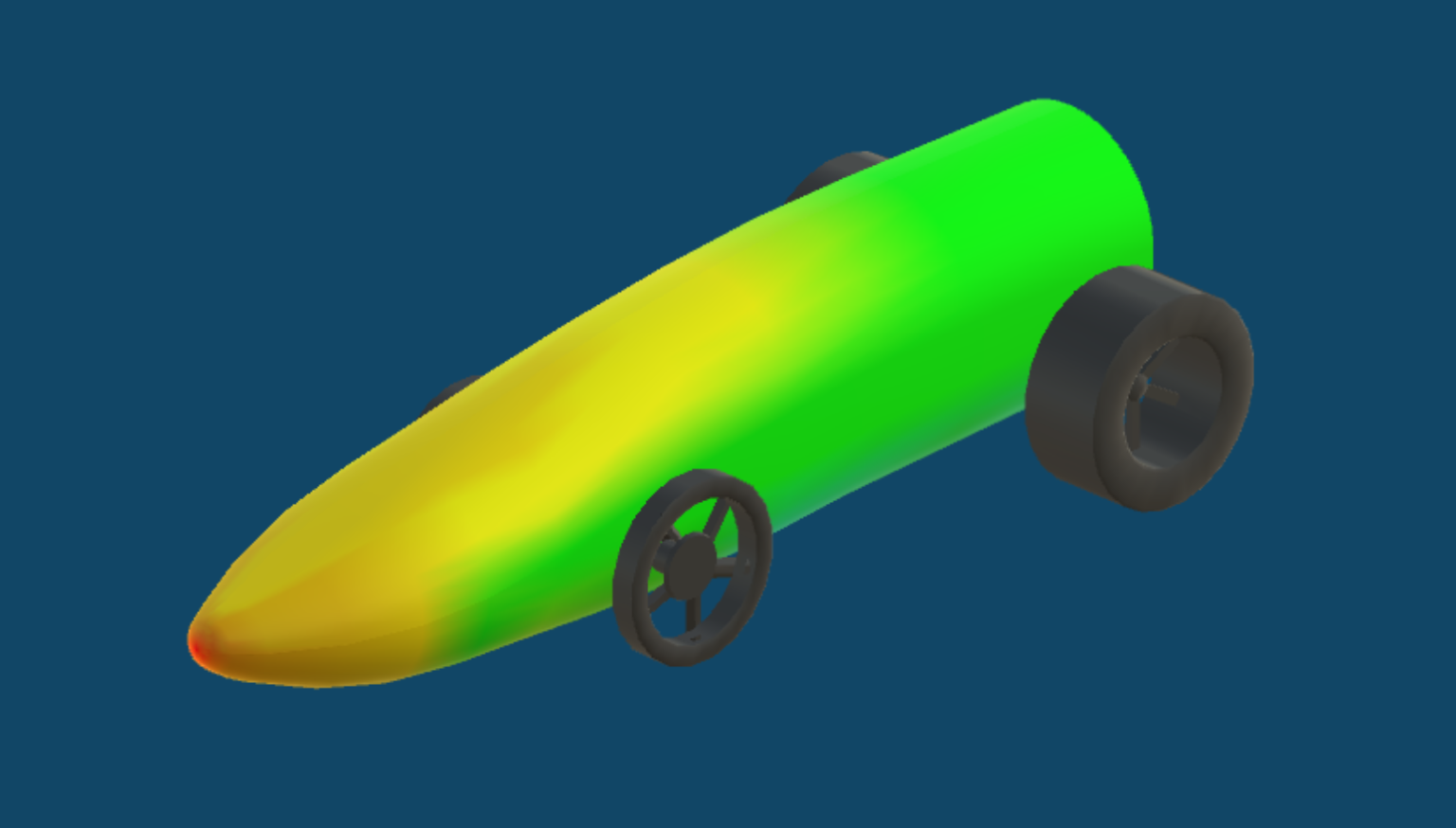

I designed my first version taking inspiration from many Formula 1 cars, but I soon found that I was going in the wrong direction. This is because, unlike the F1 cars that are driven by the wheels, the dragsters that we are supposed to build will be propelled by a CO2 canister that generates a backward force. So instead of thinking of this dragster as a car, I soon realized that a bullet would better match the profile I was going after.

Getting the dragster on the ground would also create friction. To keep the car on the ground without creating as much friction, I raised the nose of the car to be positioned higher so that the air resistance would do the work of leveling the dragster. Going back to what I mentioned, a bullet has good aerodynamics because the bullet tip is carefully designed to gradually streamline the bullet for the most stability and minimize air friction. So, theoretically, the fastest design of the dragster would be the lightest, shortest, and shaped like a bullet with wheels.

Currently, we have finished the design stage. Below are the design and racing results of my car, simulated on the computer. We have yet to build a physical car using actual materials.

Racing

Racing is an also an important part of creating dragster. You never know if something is going to succeed if you don’t test it. Testing can also create inspiration for faster designs. Quickly, I discovered that none of my classmates’ cars could beat mine, so I started to compete with students outside my class, in the entire Cooper Middle School. Soon, I found cars that could beat my dragster, so I adjusted my car until it became the first in the school. But I didn’t stop there, but moved further and started competing against myself, seeking the fastest dragster possible. Below is a picture of two of my own cars racing each other.

Wooden prototype (updated Feb 2025)

Below is the picture of the actual car made following my design (with the CO2 canister removed). In the real world, the performance of the dragster deviates from what is predicted by simulation. No engineer can perfectly model the real world scenario.